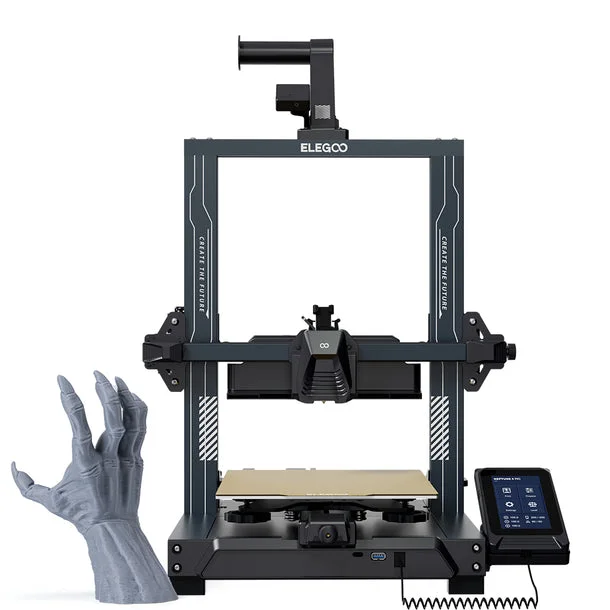

Elegoo Neptune 4 Pro 3D Printer

26500EGP

0 From 5 Stars

Neptune 4 Pro: 500 mm/s Klipper Power with Dual Heating Zone Technology

The Elegoo Neptune 4 Pro is the advanced version of the high-speed Neptune series, built for users demanding efficiency and precision. It features a high-performance ARM 64-bit quad-core mainboard and Klipper firmware to reach speeds up to 500 mm/s. What truly sets the Pro apart is its smart Dual Heating Zone bed and All-Metal Guide Rails on the X and Y axes, providing superior stability and optimized power consumption.

Pro Grade Upgrades for Stability and Efficiency

- Smart Dual Zone Heating: The 250W heated bed features two independent heating areas (100W + 150W). This intelligent system automatically detects model size and heats only the necessary area, significantly reducing power consumption.

- All-Metal Guide Rails: Both X and Y axes utilize robust all-metal guide rails with U-shaped steel wheels, ensuring maximum precision, minimal drag, and superior durability compared to standard POM wheels.

- Klipper Performance: Runs on a powerful 64-bit 1.5G Quad-Core mainboard, enabling speeds up to 500 mm/s and offering advanced control via LAN network/WEB terminal.

- Thermal Mastery: 300 °C All-Metal High-Temp Hotend with a copper-titanium heat break, supporting materials like ABS, TPU, and Nylon without performance issues.

- High-Force Extrusion: Elegoo's proprietary Dual Gear Direct Drive Extruder (5.2X extrusion ratio) provides reliable, high-accuracy filament feed.

- Full Automation: Features 121-point (11x11) Automatic Levelling and smart functions like Filament Detection Sensor and Smart Resume Printing.

Your Authorized Source for the Neptune 4 Pro in Egypt

For a machine with advanced components and smart power management, reliable local support is key. As an Authorized Reseller for Elegoo, we ensure you get genuine products and full protection:

- Guaranteed Local Warranty: Comprehensive 1-Year Local Warranty, fully backed by the official manufacturer’s network.

- Pro Maintenance: Priority service for Dual Zone Bed and All-Metal Rail maintenance via our dedicated Maintenance & Parts service.

- Klipper Training: Specialized Training Courses focusing on Klipper optimization and high-temp material printing.

Official Technical Specifications

- Build Volume (LWH): 225 x 225 x 265 mm

- Motion System: All-Metal Guide Rails (X and Y Axes)

- Mainboard: ARM 64-bit 1.5G Quad-Core (Klipper Firmware)

- Max Print Speed: ≤ 500 mm/s (Recommended: 250–300 mm/s)

- Max Print Temperature: 300 °C (All-Metal High-Temp Hotend)

- Max Heated Bed Temp: 110 °C (250W Heater)

- Heated Bed Feature: Dual Independent Heating Areas (100W + 150W)

- Extruder: Self-Developed Dual Gear Direct Drive

- Levelling: 2.0 Automatic Levelling (121 Points)

- Cooling System: 6 High-Power Fans with Intelligent Control

- Supported Materials: PLA, PETG, TPU, ABS, Nylon (Wide Range)

- Connectivity: USB, LAN (for remote control), WiFi (Optional)

- Z-Axis: Dual Z-Axis Motors with Leadscrews