3D Printing in Engineering

3D Printing in Engineering

Introduction to 3D Printing

3D printing, also commonly referred to as additive manufacturing, is a transformative technology that creates three-dimensional objects through a layer-by-layer process. This innovative technique has significantly evolved since its inception in the 1980s, when Charles W. Hull developed the first stereolithography apparatus (SLA), granting the ability to produce intricate designs directly from digital models. Over the years, 3D printing has matured into a robust and versatile technology, with numerous methods now employed across various sectors.

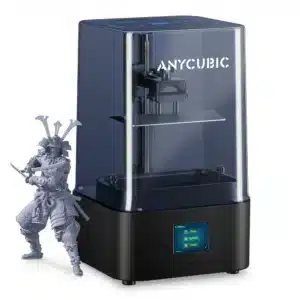

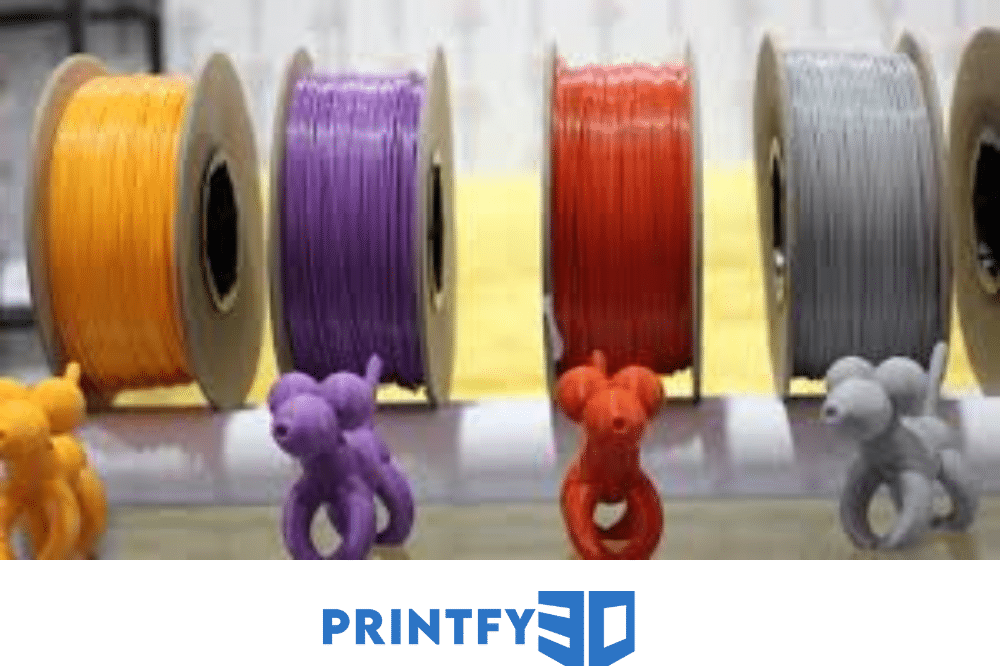

The foundational principle of 3D printing involves the same basic steps: a digital model is sliced into thin horizontal layers, which are then printed sequentially to build the object from the ground up. The various types of 3D printing methods, including Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS), each utilize distinct mechanisms suited to specific applications. FDM, for instance, extrudes melted thermoplastic materials through a nozzle, allowing for efficient and cost-effective prototyping. On the other hand, SLA employs a UV light source to cure photopolymer resin layer by layer, resulting in high-resolution prints suitable for intricate details.

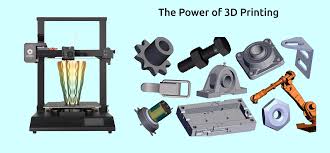

Selectively, SLS uses a laser to fuse powdered materials, such as plastic, metal, or ceramics, ensuring strong and durable pieces ideal for industrial applications. The advantages of 3D printing extend beyond mere manufacturing efficiency; they include rapid prototyping, the customization of parts, reduced waste, and the capacity to produce designs that would be otherwise impossible using traditional methods. As industries embrace this technology, its usage scales, leading to innovations in fields ranging from aerospace and automotive to medicine and construction.

Understanding the core concepts of 3D printing is critical, as it sets the stage for examining its profound implications in engineering and its potential to revolutionize design and manufacturing processes.

Impact on Design and Prototyping

Impact on Design and Prototyping

3D printing has fundamentally transformed the design and prototyping stages within the engineering sector, offering significant advantages over conventional manufacturing methods. Often referred to as additive manufacturing, 3D printing allows for rapid prototyping, which is crucial for engineers aiming to refine and enhance their designs. With this technology, prototypes can be created in a matter of hours or days, as opposed to weeks or months, which significantly accelerates the development process. This speed not only reduces time-to-market for new products but also enables a more iterative design approach where engineers can experiment with multiple variations before settling on a final design.

The capacity of 3D printing to fabricate intricate geometries that would be impossible to achieve through traditional machining methods further accentuates its role in engineering. Designers are now able to create components with complex structures, such as lattice frameworks and conformal cooling channels, which offer better performance and efficiency. These advanced designs can lead to lighter, stronger, and more efficient products, which are increasingly vital in industries like aerospace and automotive manufacturing, where weight and performance are critical.

Several industry leaders have successfully integrated 3D printing into their development cycles. For example, GE Aviation has utilized additive manufacturing to produce fuel nozzles for jet engines, resulting in parts that are both more lightweight and efficient than their traditionally manufactured counterparts. Similarly, the automotive giant, Ford, has adopted 3D printing for producing rapid prototypes of various components, allowing their engineers to assess fit and functionality with unprecedented agility. These case studies underscore not only the transformative impact of 3D printing on design and prototyping but also its potential for innovation across various engineering sectors.

Materials and Sustainability

3D printing has revolutionized the way engineering utilizes materials, providing a platform for the development of innovative approaches to sustainability. Various materials, including plastics, metals, and composites, can effectively be used in 3D printing processes, each offering unique properties that cater to specific engineering needs. Plastics, such as polylactic acid (PLA) and acrylonitrile butadiene styrene (ABS), are often employed due to their ease of processing and moderate strength. These materials are particularly appealing for prototyping and small-scale production, contributing to lower energy consumption compared to traditional manufacturing techniques.

Metals, on the other hand, present an exciting frontier for 3D printing in engineering. Materials like titanium, aluminum, and stainless steel can be precisely fabricated using additive manufacturing technologies. These metals are particularly valuable in industries that demand high performance, such as aerospace and medical engineering. The ability to create complex geometries with reduced material wastage positions 3D printing as a favorable alternative for sustainable engineering practices.

Moreover, composites combine the advantageous properties of different materials to enhance performance while minimizing weight. For example, carbon fiber reinforced materials demonstrate exceptional strength-to-weight ratios, making them ideal for applications in automotive and aerospace sectors. The use of composites in 3D printing not only allows for high-performance parts but also supports sustainable practices by reducing the amount of material required during production.

One of the most significant advantages of 3D printing lies in its capacity for waste reduction and energy savings. Traditional subtractive manufacturing often results in substantial material waste, whereas additive manufacturing constructs parts layer by layer, effectively utilizing only the necessary amount of material. Additionally, the ability to produce parts on-demand significantly lowers inventory requirements, further minimizing environmental impact. By embracing these advanced materials and their sustainable attributes, engineering can significantly contribute to a more eco-friendly future.

Future Trends and Innovations

The future of 3D printing in engineering is marked by a remarkable convergence of emerging technologies and innovative practices. One of the key advancements is bioprinting, which utilizes 3D printing techniques to fabricate living tissues and organs. This has the potential to revolutionize regenerative medicine, allowing for personalized grafts and transplants tailored specifically to individual patients. As this technology matures, its integration into the healthcare sector could transform surgical practices and enhance patient outcomes.

Future Trends and Innovations

Advancements in materials science are also pivotal in driving the next wave of innovation in 3D printing. Researchers are developing new materials that possess enhanced strength, flexibility, and thermal properties, broadening the scope of applications. For instance, the introduction of bio-compatible polymers and metal composites will enable engineers to explore previously unattainable applications in aerospace and automotive industries. These materials will not only facilitate the production of lighter and more durable parts but also contribute to the sustainability of engineering practices.

Integration with artificial intelligence (AI) and machine learning is another trend that is shaping the future of 3D printing. By harnessing the capabilities of AI, engineers can optimize the design process, predict potential failures, and improve quality control. Machine learning algorithms can analyze extensive data sets to identify the most efficient printing parameters, resulting in enhanced precision and reduced material waste. This synergy between 3D printing and AI is set to streamline production processes and lead to significant cost reductions.

However, this evolution is not without its challenges. Issues such as intellectual property rights, regulatory constraints, and the need for standardized practices must be addressed to fully leverage the potential of 3D printing in engineering. Solutions to these challenges will pave the way for the mass customization of products, enabling manufacturers to meet specific consumer needs efficiently while maintaining quality and reliability.