?Filaments – Which Type Should I Use

?Filaments – Which Type Should I Use

Choosing the Right Filament for Your 3D Printing Needs

?Filaments – Which Type Should I Use

Introduction to 3D Printing Filaments

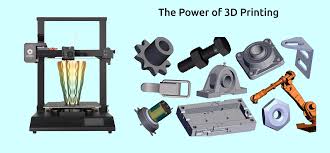

3D printing has revolutionized the production and design landscape, enabling users to create intricate three-dimensional objects layer by layer. The fundamental component in this remarkable process is the 3D printing filament, a material that is heated and extruded through the printer’s nozzle to build up the desired form. The quality, characteristics, and performance of a printed object largely depend on the type of filament used, making the selection of the right material a critical aspect of 3D printing.

3D printing filaments come in various compositions and properties, each tailored to meet specific printing requirements and objectives. Common materials include polylactic acid (PLA), acrylonitrile butadiene styrene (ABS), and nylon, among others. These filaments vary greatly in elasticity, strength, durability, and ease of use, catering to a diverse range of applications. For instance, PLA is praised for its ease of printing and environmentally friendly nature, while ABS is often favored for its toughness and resilience, making it suitable for more demanding applications.

The properties of 3D printing filaments also play a crucial role in defining the surface finish, adhesion, and overall aesthetic of the printed object. Factors such as temperature resistance, flexibility, and impact resistance must be considered when choosing a filament for a particular project. Furthermore, advancements in material science have led to the development of specialty filaments that offer unique features like conductivity, transparency, or composite properties, thus broadening the horizons for creativity and functionality in 3D printing.

In essence, understanding the various types and properties of 3D printing filaments facilitates informed decision-making for users, allowing them to select the most appropriate material that meets their project needs and ensures high-quality outputs.

Common Types of 3D Printing Filaments

When it comes to 3D printing, the choice of filament is a crucial factor that influences the quality, durability, and functionality of the printed object. Several types of filaments are widely used in the industry, each with distinct characteristics, advantages, and disadvantages. This article will examine four popular filaments: PLA, ABS, PETG, and TPU, to assist in determining the most suitable option for various printing needs.

PLA, or Polylactic Acid, is a biodegradable thermoplastic derived from renewable resources like cornstarch. One of its primary advantages is its ease of use; PLA prints at lower temperatures and adheres well to the printing surface, making it a preferred choice for beginners. However, PLA is less heat-resistant and can deform under high temperatures, making it less ideal for functional prototypes or outdoor applications.

On the other hand, ABS, or Acrylonitrile Butadiene Styrene, is known for its strength and durability. It can withstand higher temperatures and is resilient to impact, making it a popular choice for functional parts. However, ABS can produce fumes while printing and may require a heated print bed to minimize warping, which can make it more challenging to work with for novice users.

Another commonly used filament is PETG, or Polyethylene Terephthalate Glycol-modified. It combines the ease of PLA and the strength of ABS. PETG offers excellent layer adhesion and is less prone to warping, making it suitable for both beginners and advanced users. Its durability and resistance to chemicals make it ideal for functional applications, yet it may require extra attention to avoid stringing during printing.

Lastly, TPU, or Thermoplastic Polyurethane, is a flexible filament used for creating rubber-like parts. This filament is celebrated for its elasticity and impact resistance, making it perfect for producing items like phone cases or wearable devices. However, printing with TPU can be more complex due to its flexibility, causing challenges such as filament slipping or jamming in the extruder.

Each of these filament types plays a pivotal role in 3D printing and can significantly influence the aesthetics and performance of finished products. Understanding their unique properties will empower users to make informed decisions in selecting the most appropriate filament for their specific projects.

Factors to Consider When Choosing a Filament

When selecting a filament for 3D printing, several critical factors play a significant role in ensuring the final product meets project requirements and expectations. One of the foremost considerations is strength and durability. The filament used directly influences the structural integrity of the printed object. For applications requiring high resilience, materials such as ABS or nylon may be suitable due to their excellent mechanical properties. In contrast, PLA is often preferred for prototypes and low-stress applications due to its more straightforward printing process, even if it offers reduced durability.

Flexibility is another important aspect to consider. Flexible filaments, like TPU or TPE, can result in products that are bendable and resilient. These are ideal for creating items that necessitate movement and adaptability, such as phone cases or wearables. However, these materials pose unique challenges during printing, requiring specific print settings and adjustments. Therefore, assessing the flexibility requirements of the intended product is essential in the filament selection process.

The ease of printing can significantly impact the efficiency of a 3D printing project. Some filaments, like PLA, are renowned for their user-friendliness, making them a staple for beginners. Conversely, materials such as nylon or PETG may necessitate precise calibration of temperatures and bed adhesion techniques. Understanding these nuances will assist users in navigating potential challenges.

Temperature resistance is yet another factor that cannot be overlooked. For applications exposed to heat, such as automotive parts or electronic enclosures, a filament with high thermal resistance, like ABS or ASA, is necessary. Lastly, the intended application defines the selection guidelines; aesthetic prints may prioritize color vibrancy and finish, while functional components demand strength and reliability. By weighing these factors carefully, one can ensure the selected filament aligns with the specific goals of the 3D printing project.

?Filaments – Which Type Should I Use

Tips for Using Different Filaments Effectively

When working with various types of filaments in 3D printing, understanding how to optimize your printing settings is crucial for achieving high-quality results. Each filament type, such as PLA, ABS, PETG, and TPU, has unique properties that require tailored settings. For instance, PLA typically prints well at temperatures between 180-220°C. It adheres easily to print beds, but to avoid warping, ensure that the bed is heated to at least 60°C. Conversely, ABS requires higher temperatures, usually around 220-250°C, and is best printed on a heated bed to minimize shrinkage.

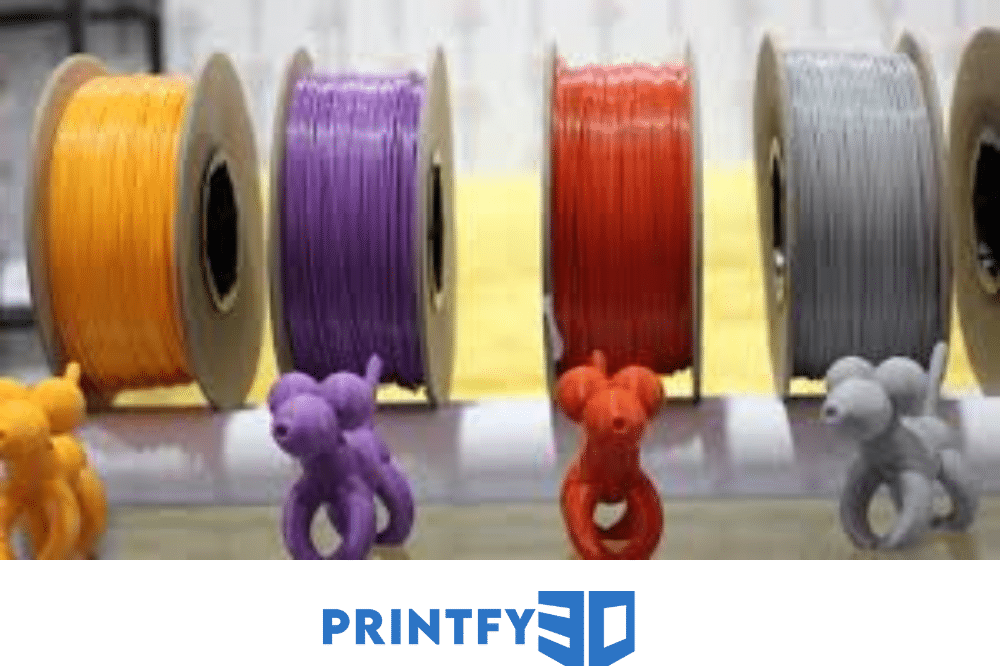

Storage is another important consideration when it comes to filament use. Many filaments are hygroscopic, meaning they absorb moisture from the air, which can lead to poor print quality. For materials like nylon and PVA, it’s advisable to store filaments in airtight containers with desiccants. PLA should be kept in a cool, dry place, while TPU, known for its flexibility, should be free from dust and contaminants to avoid clogs during printing.

Post-processing techniques also play a significant role in finishing touches. For instance, ABS can be smoothed with acetone vapor, resulting in a glossy surface finish. PLA may benefit from sanding and painting, while PETG can be acetone vapor smoothed for a translucent finish. Troubleshooting common issues is essential as well. If you experience stringing with PLA, reducing the printing temperature or increasing retraction can help. For ABS, warping may occur due to a cooling print environment; thus, using an enclosure can mitigate this issue effectively.

By understanding the distinct requirements of each filament type, from optimal printing settings to proper storage and effective post-processing techniques, users can significantly enhance their 3D printing outcomes, making each project a successful endeavor.