3D printers in Egypt

3D printers in Egypt

The Rise of 3D Printers in Egypt: Revolutionizing Manufacturing and Innovation

Introduction to 3D Printing

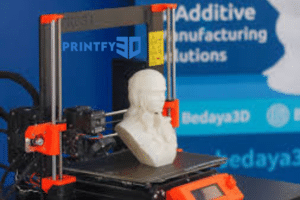

3D printing, also known as additive manufacturing, is a groundbreaking technology that enables the creation of three-dimensional objects from digital files. This process involves layering materials, such as plastics, metals, or ceramics, to build an object layer by layer, which distinguishes it from traditional manufacturing methods that often rely on subtractive processes. The core of 3D printing technology lies in its ability to facilitate efficient production and customization of complex shapes that were previously difficult or impossible to achieve.

The operational mechanism of 3D printing typically begins with a computer-aided design (CAD) file. This digital blueprint is processed by a slicing software that converts it into a set of instructions for the 3D printer. The printer then uses these instructions to deposit materials precisely, resulting in a three-dimensional object that mirrors the original design. There are various 3D printing technologies, including Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS), each suitable for specific applications and materials.

3D printing has found extensive applications across diverse industries. In healthcare, it is used to create customized prosthetics and implants, revolutionizing patient care. The aerospace sector utilizes 3D printing for producing lightweight components, enhancing fuel efficiency. Moreover, the automotive industry employs this technology for rapid prototyping and manufacturing complex parts, significantly reducing production time and costs. Beyond these sectors, 3D printing is increasingly making its mark in architecture, fashion, and even food production, showcasing its versatility and potential for innovation.

3D printers in Egypt

With its growing presence in various fields, the adoption of 3D printing technology in Egypt is set to transform local manufacturing practices. By exploring global trends and advancements in 3D printing, this blog aims to highlight the transformative effect it can have within the Egyptian context.

The Current State of 3D Printing in Egypt

As of 2023, the landscape of 3D printing in Egypt has witnessed significant growth, marking a pivotal transformation in the local manufacturing ecosystem. The adoption of this technology has been increasingly prevalent in various sectors, including healthcare, architecture, education, and automotive industries. Various businesses and educational institutions are now harnessing the capabilities of 3D printers, propelling innovation and enhancing operational efficiencies.

Currently, numerous startups and established companies are utilizing 3D printing to create prototypes, custom parts, and intricate designs. The healthcare sector, in particular, has embraced this technology, utilizing it to produce dental implants, prosthetics, and even bioprinted tissues. Educational institutions have also played a crucial role in the proliferation of 3D printing. Many universities and technical schools have integrated 3D printing into their curricula, facilitating hands-on learning opportunities for students in engineering and design fields.

Furthermore, Egypt’s strategic efforts to position itself as a hub for technological innovation have led to collaborations with international companies and organizations. Recent developments include the establishment of specialized research centers focusing on advancing 3D printing materials, techniques, and applications. These initiatives are also supported by local government policies aimed at fostering an entrepreneurial environment conducive to innovation.

Moreover, various sectors have begun to recognize the potential cost savings and design flexibility that 3D printing affords. The construction industry, for example, has started exploring 3D printing technologies for building elements, aiming to address the nation’s housing challenges. As a result, the integration of 3D printing in Egypt is not only revolutionizing manufacturing processes but also laying the groundwork for future advancements in diverse fields.

Key Industries Utilizing 3D Printing in Egypt

In recent years, 3D printing technology has established a significant presence across various sectors in Egypt, leading to remarkable advancements in manufacturing and innovation. One of the industries most profoundly affected is healthcare. In particular, the production of prosthetics has seen transformative changes, allowing for customized solutions tailored to individual patients. This capability not only enhances the comfort and usability of prosthetic limbs but also significantly reduces costs associated with traditional manufacturing methods. Additionally, the dental industry is leveraging 3D printing to create precise dental models and implants, thereby streamlining procedures and improving patient outcomes.

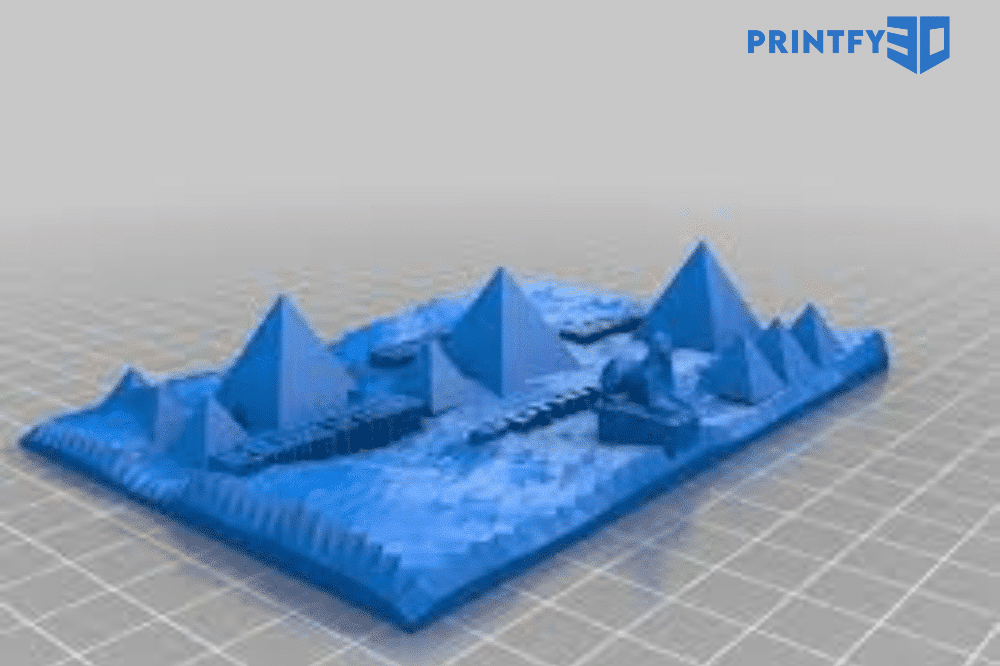

Architecture is another key sector that is benefiting from the implementation of 3D printing in Egypt. Architects and designers are able to create intricate models and prototypes that allow for effective design revisions and client presentations. This technology facilitates faster project timelines and enables a more sustainable approach to building practices, utilizing less material waste compared to conventional methods. The use of 3D-printed components also extends to construction, where structural elements can be fabricated with enhanced efficiency and reduced labor costs.

Education is not left behind in this innovative wave; educational institutions are incorporating 3D printing into their curricula. Students across disciplines, from engineering to art, are gaining hands-on experience with this technology, fostering creativity and practical skills. The ability to print models and prototypes promotes an engaging learning environment, encouraging students to explore and experiment.

In general manufacturing, various sectors are adopting 3D printing to streamline production processes and facilitate rapid prototyping. This adaptability allows manufacturers to respond quickly to market demands and optimize their supply chains. Thus, it is clear that the integration of 3D printing into key industries in Egypt is reshaping traditional paradigms, promoting efficiency, customization, and economic viability in manufacturing and beyond.

3D printers in Egypt

Challenges Facing 3D Printing in Egypt

While 3D printing technology holds significant potential for transforming the manufacturing landscape in Egypt, several challenges impede its widespread adoption. One of the primary hurdles is the high cost associated with acquiring and operating 3D printers. Many businesses, especially small and medium enterprises (SMEs), face financial constraints that make it difficult to invest in such advanced technologies. The initial investment can be prohibitive, and ongoing costs related to maintenance, materials, and training further complicate the situation.

Another challenge is the limited access to cutting-edge 3D printing technology. Many regions in Egypt lack adequate infrastructure to support advanced manufacturing practices. This includes not only the machines themselves but also access to high-quality printing materials and software. Without the necessary resources, companies may struggle to leverage the full capabilities of 3D printing, thus stunting innovation and growth.

The absence of a skilled workforce poses an additional obstacle. While the awareness of 3D printing technology is growing, there remains a significant gap in expertise and training within the local labor market. Educational institutions are gradually incorporating 3D printing into their curricula; however, the pace of change is slow. This skills gap affects not only operator proficiency but also limits the capacity for research and development efforts necessary for advancing the technology in local industries.

Finally, regulatory hurdles can further stifle the growth of 3D printing in Egypt. Existing regulations may not be adequately designed to accommodate the rapid evolution of additive manufacturing technologies. Policymakers need to establish a legal framework that balances innovation with safety, intellectual property rights, and environmental considerations. Addressing these regulatory issues will be essential for fostering an environment that encourages investment and growth in the 3D printing sector.

Success Stories and Innovations

The adoption of 3D printing technology in Egypt has given rise to numerous success stories that reflect its transformative impact on manufacturing and innovation. Various sectors, including healthcare, education, and engineering, have begun to leverage this technology to enhance efficiency and creativity in product development.

One notable success story comes from Cairo-based startup “Vertical Farming Egypt,” which utilizes 3D printing to develop sustainable agricultural solutions. They have designed and manufactured custom hydroponic systems that are both cost-effective and efficient. By integrating 3D printing into their production process, they can rapidly prototype and produce components that are tailored to specific agricultural needs, significantly reducing waste and production time. This innovative use of technology has positioned them as leaders in urban agriculture, inspiring other startups to explore similar avenues.

In the realm of healthcare, the Ain Shams University hospitals have made considerable strides in utilizing 3D printing for medical applications. The orthopedics department has successfully printed patient-specific prosthetics and orthopedic implants, drastically improving the fit and comfort for patients. This innovation not only enhances the quality of care but also reduces the waiting time and costs associated with traditional manufacturing methods. Such advancements in medical applications showcase the potential of 3D printing to revolutionize healthcare delivery in Egypt.

Furthermore, educational institutions are playing a pivotal role in fostering a culture of innovation through 3D printing. The American University in Cairo has incorporated 3D printing technology into its engineering curriculum, allowing students to gain hands-on experience with the tools that are reshaping the manufacturing landscape. Student projects often result in practical solutions to real-world problems, demonstrating the immense potential of this technology in inspiring the next generation of innovators.

Through these examples, it becomes evident that the ecosystem of 3D printing in Egypt is thriving, with local businesses, universities, and startups at the forefront of this technological revolution. As more entities recognize the benefits of integrating 3D printing into their operations, the potential for growth and innovation is boundless.

3D printers in Egypt

Future Prospects for 3D Printing in Egypt

The potential for growth in 3D printing technology within Egypt is increasingly promising, driven by advancements in both technology and the broader manufacturing landscape. As Egypt continues to develop its infrastructure and technological capabilities, there are significant opportunities for 3D printing to play a vital role in various sectors, including healthcare, construction, and consumer goods. The ability to produce customized and complex designs with precision will increasingly attract manufacturers looking for efficiency and innovation.

One of the most notable trends is the migration towards localized manufacturing solutions. With 3D printing, companies can embrace a decentralized production model that allows them to produce goods closer to the end consumer. This can effectively reduce transportation costs and delivery times, leading to a more sustainable and responsive supply chain. Furthermore, government initiatives towards fostering a robust manufacturing sector will likely create a favorable environment for the adoption of 3D printing technologies.

As the technology evolves, we can expect advancements such as faster printing speeds, improved materials, and more user-friendly software. Public and private investment in research and development is also anticipated to enhance the capabilities of 3D printers. The growth of educational programs focused on additive manufacturing will cultivate a skilled workforce capable of driving innovation in the industry. With increasing awareness and accessibility, small and medium-sized enterprises could leverage 3D printing to compete with larger manufacturers, thus democratizing the market.

Moreover, the integration of 3D printing within traditional industries can revolutionize how products are designed and manufactured. Businesses will likely harness the technology to create prototypes, tools, and even finished products that meet local demands. The blending of traditional craftsmanship with modern 3D printing techniques could set new standards in quality and creativity. As these trends develop, it becomes clear that the future of 3D printing in Egypt holds substantial promise, leading to a transformation in the economic landscape of the region.

Education and Training in 3D Printing

The rise of 3D printing technology in Egypt has underscored the importance of education and training programs aimed at developing a skilled workforce adept in this innovative manufacturing process. Universities and technical schools across the country have begun to integrate 3D design and printing technologies into their curricula, positioning themselves at the forefront of this technological evolution. By providing students with foundational knowledge and hands-on experience in additive manufacturing techniques, educational institutions are playing a pivotal role in equipping future professionals with the necessary competencies to thrive in this field.

Several universities in Egypt have established specialized programs dedicated to 3D printing, offering courses that cover various aspects of the technology, from design principles to the mechanics of different printing methods. This academic focus is crucial in fostering a deep understanding of 3D print applications, which span multiple sectors including engineering, healthcare, and architecture. Additionally, collaborations between academia and industry have emerged, creating opportunities for students to engage in real-world projects, thereby bridging the gap between theoretical knowledge and practical skills.

Moreover, technical schools and workshops complement academic offerings by providing short-term courses that target adult learners and industry professionals seeking to upgrade their skills. These programs emphasize practical training, enabling participants to gain proficiency in operating 3D printers, utilizing design software, and troubleshooting production challenges. Such initiatives are vital in addressing the skills gap within the manufacturing sector, ensuring that the workforce is not only familiar with the technology but also capable of innovating and pushing the boundaries of what 3D printing can achieve.

In conclusion, the synergy between educational institutions and industry in Egypt is vital for harnessing the full potential of 3D printing technology. As the landscape of manufacturing continues to evolve, a robust emphasis on education and training will ensure that Egypt remains competitive and innovative in this rapidly advancing field.

Government Initiatives and Support

The Egyptian government has increasingly recognized the potential of 3D printing technology as a means to enhance manufacturing capabilities and spur innovation across various sectors. A range of policies and initiatives has been put in place to support the development of this burgeoning sector. One of the key strategies has been the establishment of innovation hubs and technology parks that are specifically designed to nurture advancements in 3D printing. These centers accelerate the research and development of new materials and processes while providing valuable resources for startups and established companies alike.

Furthermore, the government has launched several grants and funding programs aimed at providing financial assistance to businesses that invest in 3D printing technologies. By facilitating access to capital, these initiatives help to lower the barriers for entry into the 3D printing market. For instance, specific grants are available for projects that focus on sustainable practices or enhancements in manufacturing efficiency, aligning with Egypt’s broader economic goals. In addition, training programs have been initiated to upskill the workforce in the essentials of 3D printing technology, ensuring that there is a pool of qualified professionals equipped to advance the industry.

Partnerships with educational institutions, both local and international, are also pivotal in bolstering the 3D printing sector. Collaborative research projects and exchange programs promote knowledge sharing and foster innovation. These efforts underscore the government’s commitment to creating an ecosystem that encourages experimentation and the application of cutting-edge technology in various disciplines, including healthcare, construction, and consumer goods. Through these multifaceted initiatives, the Egyptian government is laying a foundation for a vibrant 3D printing landscape that holds promise for economic diversification and technological advancement.

Conclusion

As we conclude our exploration of the rise of 3D printers in Egypt, it is evident that this technology is not merely a passing trend but a significant driver of innovation and manufacturing within the country. The integration of 3D printing into various sectors presents a myriad of opportunities for Egyptian businesses, startups, and educational institutions, enhancing their ability to produce prototypes, customized solutions, and even final products at an unprecedented pace and cost-effectiveness. This ongoing evolution reflects a broader global movement towards digital manufacturing, where agility and creativity are paramount.

The implications of adopting 3D printing technology extend beyond immediate economic benefits; they also align with Egypt’s goals for modernization and competitiveness in the international market. The fostering of local talent and expertise in additive manufacturing is crucial, as it empowers a new generation of engineers, designers, and entrepreneurs to innovate and solve unique challenges faced by the local industry. Moreover, advancements in 3D printing can significantly reduce waste and the carbon footprint associated with traditional manufacturing processes, promoting sustainability and environmental responsibility.

Despite the exciting potential, it is important that stakeholders approach this technological shift with a sense of responsibility. Ensuring that the benefits of 3D printing are accessible to all, while maintaining ethical standards and considerations in its application, is essential for fostering inclusivity in this evolving landscape. As Egypt continues to invest in and embrace advanced manufacturing technologies, it stands at the cusp of a transformation that can position the nation as a leader in innovation within the region. The journey of integrating 3D printing into the fabric of Egyptian manufacturing will undoubtedly shape the future of various industries and contribute to the nation’s overall development.